What is Filter Bag?

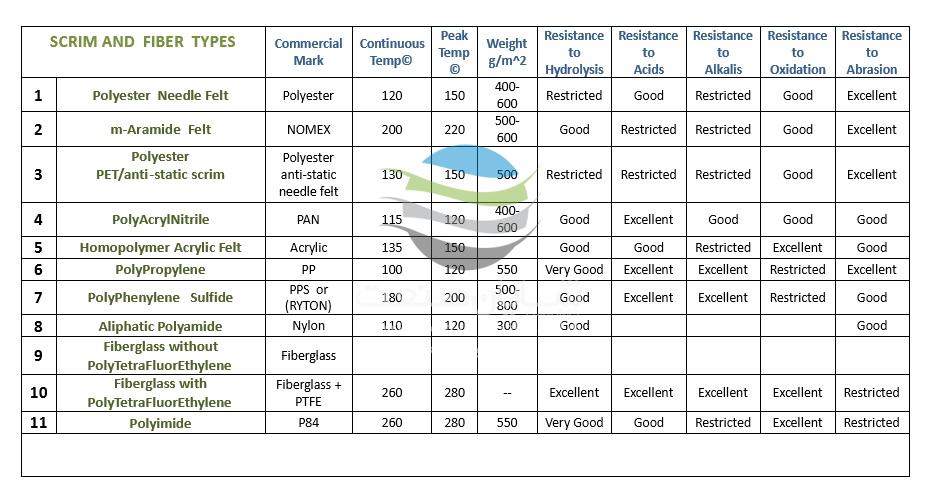

These types of filters are made with different shapes and sizes, generally made of woven fabric or a felted fiber made of natural, synthetic or inorganic fibers, such as polyester or polypropylene. These types of filters are used for particles with a diameter of about 5 microns. If they are designed properly, they will have a refining efficiency of 95%.

The bag filter is capable of providing decent air flow rates of 25% to 150% of its nominal capacity, which is particularly suitable for use in variable air volume systems. The bag filters can provide a low pressure drop of up to 8,000 hours of work.

Bag houses are an example of bag filters that are based on the same as ordinary bag filters.

These filters appear in different shapes and sizes, baghouses are made up of a series (4 to 8 bags) of felt and woven fabric bags that are placed in a cage in a metallic cavity. The type of fabric used is often made of nylon, orlon, acrylic, dacron, teflon or fiberglass.

The main advantage of this type of filter is the less effective exhaust gas consumption by changing the inlet gas characteristics and easier access to lower output mist in the range

10 mg per cubic meter.

Used in these types of filters in the cement, rubber, petrochemical, steel industries, various powder production industries and special applications including air conditioners of factories, factories, warehouses, chain stores, offices, public buildings, hospitals, laboratories, air purifier for injectors of gas turbines , Compressors and motors. These filters are used for preliminary purification of the intake air of cabin spray paint, from fine filters or filters, hepa, alg and activated carbon.