In addition, their shelf life is usually longer than the useful life of upstream units such as furnaces, mills, dryers and coolers.

The introduction of industries that can use ESP to dump is as follows:

1- Production plants such as cement factories, lime, gypsum and … in furnaces, mills, dryers and coolers.

2. Coal or organic fuel boilers.

3. Furnaces for refuse and sludge.

4- Iron and steel industries.

5. Manufacturing factories in the pulp and paper industry.

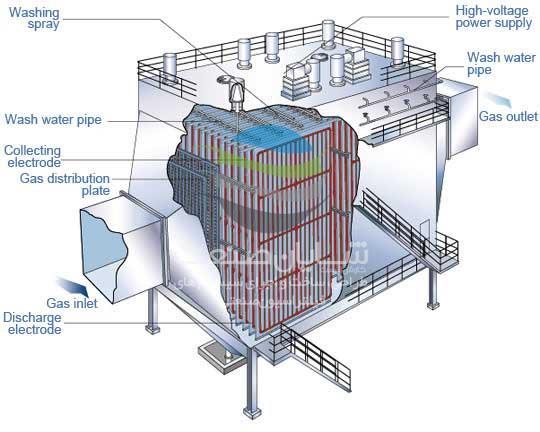

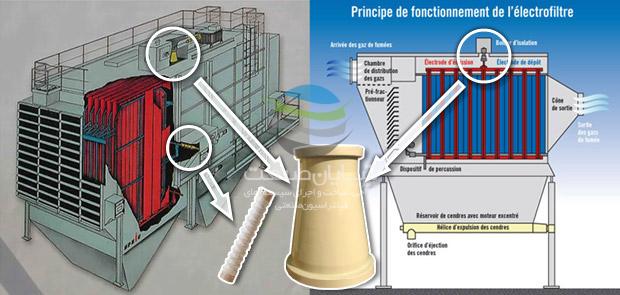

Description of the work of an electrofilter device:

The electrons are emitted from the discharge electrodes – or discharged electrodes – that are condensed with a high negative voltage. These electrons move towards the collector plates and, in their path, collect on particles of dust, they also convey the particles with negative charge. The electric field transmits the charged particles to the collector plates that are arranged, and dust particles are deposited on these plates. Then, with a regular hammer, the dust collected in the hoppers is poured through the material transfer systems.

Effective factors in electro-filter efficiency are:

Temperature, sex and gas volume, humidity and particle type

The return of electro-filter unit 1 in aqueous cement daily is about 300 to 200 tons, and this material is fed again as feed of the furnace. Due to the difference in the analysis of these materials with the raw materials and the intense grain grains, the control of the production process in terms of formulation with extra The return of the electro-filter becomes more difficult. Particularly in units lacking a suitable system, this effect is more pronounced due to the lack of uniformity of materials and compulsory changes in fuel consumption, fuel consumption and furnace load, thermal shock, and reduced The useful life of refractory bricks and the early stopping of the furnace. In the current work, the identification of returning electrons The filters include the minerals structure and aggregation of the unit of a cement aquifer complex, and using these findings, we tried to use the materials appropriately.