Converting Electric Filters to Hybrid Filters – Part II

Conversion of the second line electrofilter of the furnace and mill of Titan factory:

The Titan Camry plant showed interest in new hybrid filter technology due to environmental regulations and the fact that its electrofilter did not comply with environmental regulations. Furnace Electrofilter – The raw material mill was built by FL Smith, and Titan executives requested that the original electrofilter be replaced with a bag filter in 1977.

Accurate focus on reducing the time of cement kiln showed that replacing the electrofilter with filter cases in the same place is not a good option, and due to the lack of space to create new filter cases, Camry Titan chose a hybrid filter in the end. The information and filter code selected are listed in the table below.

| Hybrid filter design information | |

| FAA 3636-145110 / T / T / L2D | Electro-filter code of FLS company |

| RC/PJ/2268/8×127/(18×9)x2x7/1/S/7LS | FLS fabric filter code |

| 3900Nm3/h | Dubai gas design |

| ePTFE with Wowen Glass 8-meter bag cover 2268 | Bags |

| 118 °C | Operating temperature |

| -400 mmWG | Static pressure |

| 0,48 kg/m3 | Gas density |

| 93 g/Nm3 | Dust load (dry based) |

Information and code of hybrid filter of Camry Titan Company

- Description of the selected hybrid filter:

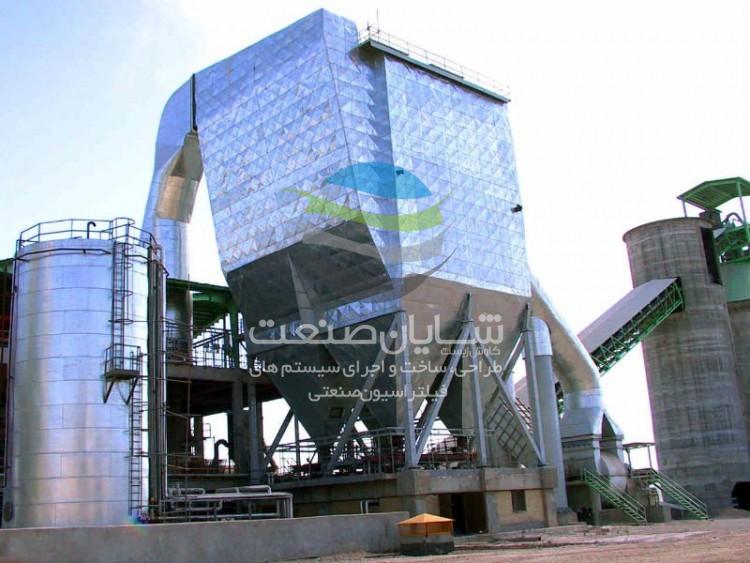

As the hybrid filter shows in the figure below, it is necessary to extend the filter cover to the part of the bag filters that needs to be exposed to an A / C ratio of about 3.1 m / min. The bags are distributed in the seven boxes at the top, and each modulator has its own output. The purpose of these output modulators is to dust in off-line conditions. These modulators are one of the most important tools for semi-inline maintenance.

Hybrid filter housing

- Flow analysis:

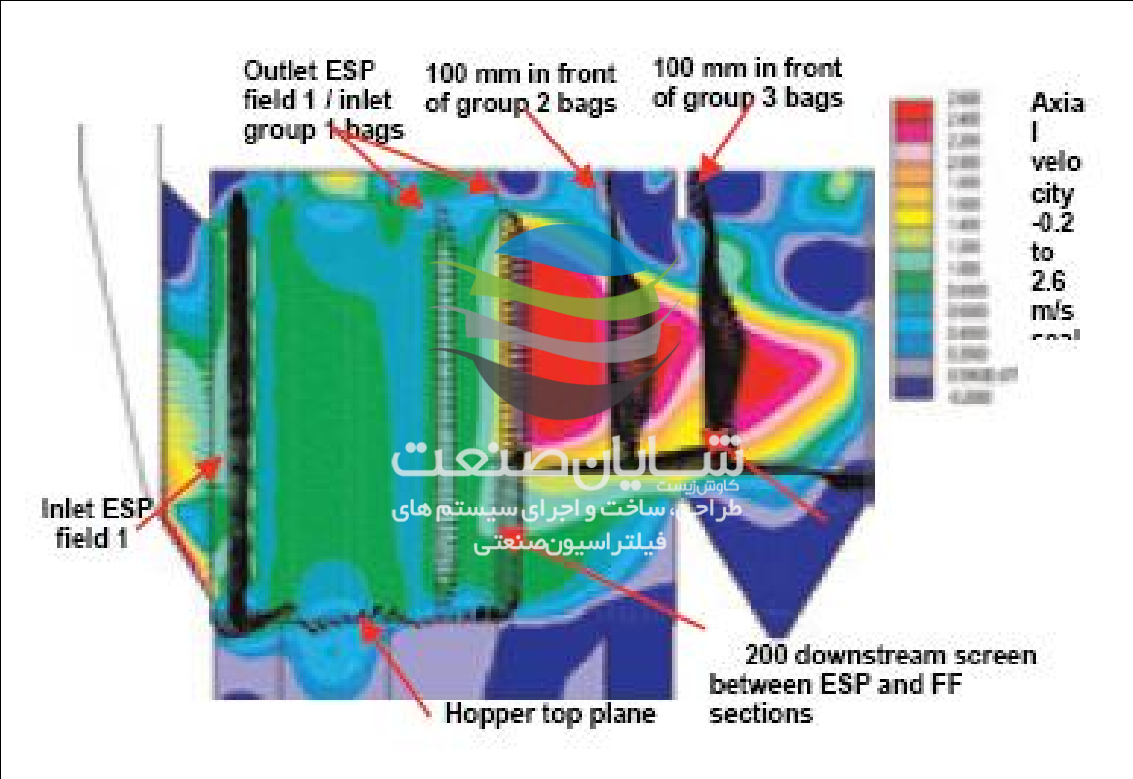

The CFD7 program is used to analyze and ensure that the gas flow pattern is under control. The results of the CFD simulation are shown in Figure (1-3). The colors indicate the flow velocity, and the scale section is on the right side of the figure below.

CFD hybrid filter simulation results

The current is completely distributed both at the filter inlet and in the electrofilter section to the fabric filter bags. The speed value is 5.2 m / s, which is an acceptable value for the bag filter inlet.

Excessive speed may cause the bags to be covered with dust or the bags to stick together or the bags to warp and should be avoided.

Performance of hybrid filters on lumbar titanium:

The filters of this company have been working for about 12 months and their efficiency is as expected. The efficiency information of these filters is given in the table below.

| Hybrid filter design information | |

| 620000m3/h | current |

| 118 °C | Temperature |

| Less than 3 g / Nm10 | Exhaust dust |

| 80-85 mmWG | Pressure drop between two flanges |

| 34 kV | Electrofilter part voltage |

| 170mA | Electrofilter part flow |

| 7239 m2 | Filter surface Filter pitchers |

| 2,5 bar | Press clean the bags |

| 1,3 – 1,4 m/min | A/C ratio |

Performance of Titan Camry Factory Hybrid Filter

Comparison of fabric filters and hybrid filters:

A new pitcher filter costs 1 euro per meter of fabric and in addition has the costs of fan, duct, chimney and installation compared to a hybrid filter. According to the table below, the cost of electricity consumption of the hybrid filter is about 40% less than the new fabric filter.

| Power consumption kW | Filter type | |

| 312 | Fan | Cloth filter |

| 30 | Compressor | |

| 342 | Total | |

| 69,4 | Electrofilter section | Hybrid filter |

| 166 | Fabric filter section | |

| 7,5 | Compressor | |

| 243 | Total | |

Comparison of power consumption of hybrid filter and fabric filter

Therefore, both in terms of initial investment and operating costs, the hybrid filter has been a good choice for the Titan Camry plant.