What is a pulse jet dust collector? Introduction and performance review

Jet pulse dust collector is one of the different types of baghouses for air pollution control that is used to collect dust and harmful gases such as sulfur dioxide in industrial environments. Usually, in order to clean the pulse jet dust collector, this filter bag does not move from its place and the dust collector bags are cleaned in a row. This is done just when a timer quickly starts firing fresh air through an opening valve. The tube in each row of the pulse jet dust bag carries the compressed air. In fact, the tube has a nozzle at the top of each bag that directs air directly into it.

What is a pulse jet dust collector?

Different components of pulse jet dust collector and check its performance

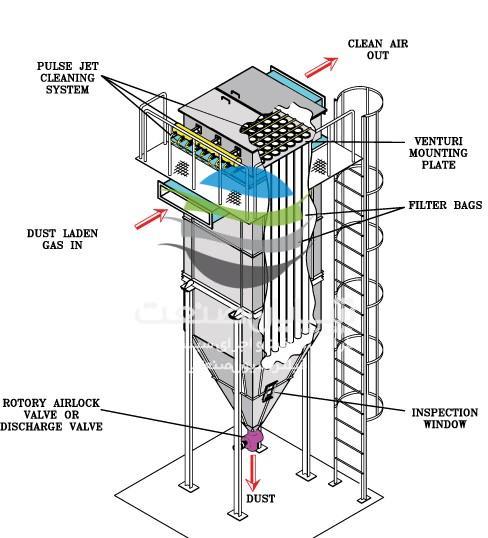

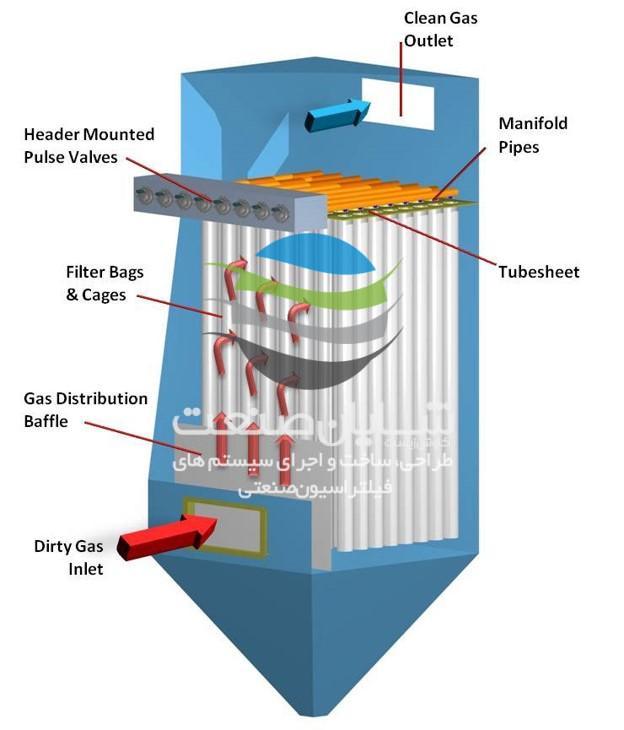

The pulse jet dust collector has six main parts: the dust filter bag, digital valves for regulating compressed air, the grille, the air ducts to the dust bag, the inlet chamber and nozzle of the contaminated gas into the dust filter and the purified gas outlet. The basic concept of fabric filtration by jet pulse dust collectors has long been used to separate solids from air and gas streams. Tubular cloth bags are widely used all over the world. These dust filter bags are placed vertically inside a chamber. Also, in order to prevent falling under vacuum or pressure, these bags are kept by metal shelves equipped with holes. The contaminated gas first enters the pulse jet dust collector and after passing through the filtration bags, clean air is directed out of the outlet nozzle. Dust particles are collected on the bags and if the dust cake thickens, the bags need to be cleaned. Pulse jet dust collectors can be cleaned continuously and without interrupting the production line by continuously directing compressed air into the chamber. Pulse jet filter bags are known as common filters that can be used in various industries. The new design of the dustproof jet pulse dust collector has resulted in longer filter bag life, lower emission levels, lower pressure drop, lower energy consumption, higher air-to-fabric ratio with better performance levels and less space required. . For Jet Pulse dust collector, it is possible to be customized and based on different application needs. Pulse Jet Bag filters are used in places where the amount of air flow is high. On the other hand, it is very difficult to use for high temperature environments. In the continuation of this MATLAB, you will learn more about the advantages and disadvantages of Jet Pulse dust collector. Please follow us to the end of the text.

Bag House Jet Pulse Diagram

Advantages and disadvantages of jet pulse dust collector

One of the most important advantages of jet pulse dust collector is the ability to clean while the production process is online. Also, the Pulse Jet Bag House is cleaned more thoroughly than the Shaker Bag Bag or reverse air. Another durability of this cleaning method is the longer shelf life of the Jet Pulse dust bag than other methods. In this model of bag house, the operation is performed with less pressure drop and also the jet pulse filter bag requires less space. In addition to the above, the most important advantages of Jet Pulse dust collector are high efficiency, low operating costs, high durability of filtration bags and resistance to gases and flammable particles. Despite the numerous advantages of jet pulse dust collectors, these filters also have various disadvantages and limitations. In the continuation of this article, the most important weaknesses of the jet pulse filter bag are pointed out.

It is important to know that pulse jet dust collectors require the use of dry compressed air for dusting operations. Also, this model of bag filter requires special fabrics for higher temperatures. Therefore, the jet pulse dust collector is limited to use for high temperature inlet gases. Although the jet pulse filter bag is highly efficient, its performance depends on the correct choice of filter and the important points necessary when installing it. . In other words, poor performance of the pulse jet dust collector can be due to faulty bag dusting system and improper equipment installation. In fact, if the capacity of the Pug House jet bag is lower than the dusting area, there is a possibility of reduced efficiency and poor filter performance. In addition, the use of incorrect air filter bags and high inlet gas humidity reduces the efficiency of pulse jet dust collectors. In fact, this type of bag filter does not tolerate high levels of humidity or high humidity in the exhaust gases. Therefore, the low efficiency of pulsed jet pulses against wet gases is one of the most important weaknesses of the operating system of this filter bag.

Pulse jet dust cleaning mechanism